Description

The Automatic Glass Sandblasting Machine utilizes a PLC computer made by SIEMENS (Germany) to control its X&Y movements and sandblast density. The computer stores up to 9 different operating programs. The operator can designate, on a given program, if only a subset or the entire glass area should be sandblasted.

Features

1. Within the same program, the Automatic Glass Sandblasting Machine can control the number of times the sprayer passes over a given area (or subset) and/or if the area (or subset) should be sprayed by one or two guns. The program also controls the speed and rate by which the glass advances.

2. The Automatic Glass Sandblasting Machine has a fourth available sprayer that can be operated manually and the glass advance controlled by foot pedal.

3. The Automatic Glass Sandblasting Machine comes with s separate free standing closed filtration system to recalculate the aluminum oxide and reduce waste.

4. The Automatic Glass Sandblasting Machine provides the user with a special wave blast application feature where the sandblasted area can be made increase/decreases in intensity smoothly.

Specifications of the Automatic Glass Sandblasting Machine

Maximum glass working size: 2300mm (Height)

Minimum Glass Size: 200 × 200 mm

Glass thickness: 2 to 50mm

Power consumption: 6KW

Power supply: 220V, 3-phase 60Hz +/- 5%

Speed: 1m2 = 3 to 4min

Working pressure: 7 to 8 bar

Compressed air consumption: 2500liter/min

(Approx 88.28 cfm) Or 20 Horsepower

Installed dimension: L7100mm × H3500mm × W2000mm

Number of Auto Guns: 3 pieces

Number of Manual Gun: 1 pc

Number of hoses: 9 pieces

Aspirator delivery: 700m3/h

Abrasive material: Aluminum oxide

Total machine weight: 2150kg

Dust collector separate from main sandblast machine

Auto-clean hoses per 3min

Wave function (sandblast glass from heavy to light)

Italy. Manufactures sandblasting and non-abrasive shot peening machines and choice of media for finishing metal, plastic, and glass surfaces. Site provides detailed information regarding available products. Manufactures moulds for the glass industry. IS machines, press, spinning machines, semi-automatic moulds. Located in Marinha Grande, Portugal. Custom powder and fusion-bonded coatings facility for the metal and glass industries. On site sandblasting and iron phosphate pretreatment.

Italy. Manufactures sandblasting and non-abrasive shot peening machines and choice of media for finishing metal, plastic, and glass surfaces. Site provides detailed information regarding available products. Glass fabrication, cutting, drilling, general machining of glass ceramics, silica and vacuum work, silvering, glass to metal seals, vacuum coating, sandblasting, and glass repairs. Custom powder and fusion-bonded coatings facility for the metal and glass industries. On site sandblasting and iron phosphate pretreatment.

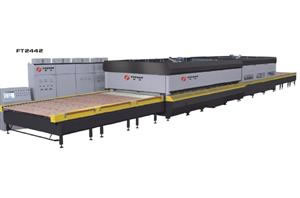

Radiation Flat Tempering Furnace FT

Radiation Flat Tempering Furnace FT

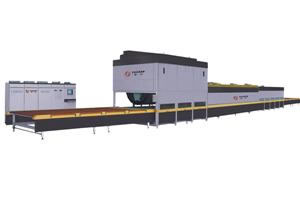

Forced Convection Flat Tempering Furnace CFT

Forced Convection Flat Tempering Furnace CFT

Combined Dual Chamber Flat Tempering Furnace SFT

Combined Dual Chamber Flat Tempering Furnace SFT

Double Row Fan Forced Convection Flat Tempering Furnace NCFT

Double Row Fan Forced Convection Flat Tempering Furnace NCFT

Double-curved Glass Bending Furnace FS-DBT

Double-curved Glass Bending Furnace FS-DBT

Radiation Flat and Bent Tempering Furnace FBTC/FBTL

Radiation Flat and Bent Tempering Furnace FBTC/FBTL

Forced Convection Flat and Bent Tempering Furnace CFBTC

Forced Convection Flat and Bent Tempering Furnace CFBTC

Forced Convection Flat and Bent Tempering Furnace CFBTL

Forced Convection Flat and Bent Tempering Furnace CFBTL

Combined Dual Chamber Flat Tempering Furnace SFT

Combined Dual Chamber Flat Tempering Furnace SFT

Glass Straight-Line Four Edger

Glass Straight-Line Four Edger