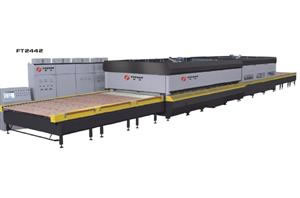

Description

The flat glass tempering furnace can be divided into electric heating glass tempering furnace, radiation flat tempering furnace and forced convection flat tempering furnace. The operation principle of glass tempering machine is to heat the plate glass first and then quick-freeze the glass; after that the compressive pressure on the surface and tensile stress inside the glass will have a joint effect on the glass to enhance the glass strength. The flat glass tempering furnace is mainly used in producing horizontal tempered glass; the radiation heating furnace and forced convection heating furnace are available as requested.

In recent years, with the rapid development of city infrastructure and civilian requirement, there is great demand for tempered glass which is widely used in show windows, doors, windows, shop fronts in offices, houses, shops, interior glass screens, partitions balustrades, and shop display.

Advantages

1. The flat glass tempering furnace is made of imported high quality thermal insulation material which can ensure the glass quality and also extend the service life.

2. Unique spiral matrix design can raise the heating rate efficiently and ensure a homogeneous heating treatment.

3. The flat tempering furnace is equipped with pass-type air grid to achieve prominent energy-saving property.

4. High-effect tuyere eliminates stress pattern.

5. This machine is equipped with uninterruptible power supply.

6. Flat glass tempering furnace adopts human-computer interface to provide a direct and convenient operation.

7. simple structure and easy maintenance