Description

The horizontal glass drilling machine can operate as a dual side driller or top-down only as desired by the operator. When in dual mode, the bottom drill is activated first and rises using an advanced damping control system that precisely engages the bottom side of the glass. Bottom-up drilling depth is controlled via an operator adjusted limit switch. Once the bottom drill has automatically released, the top drill starts and is manually lowered by the operator.

Features

1. The horizontal glass drilling machine offers 6 different operating speeds for varying diameters and glass thickness. The unit comes with stop guides for repetitive drilling.

2. The horizontal glass drilling machine has a unique water floatation system for maneuvering thin glass. This system can also be used for preparing the drill table area and assuring there is no leftover debris that may scratch the glass.

3. With a table height of only 3’, the horizontal glass drilling machine is ideal for loading and drilling glass of all shapes and sizes.

Designs and manufactures horizontal earth boring machines, horizontal directional drills, and drilling fluid mixing, pumping, and cleaning systems. Provides machine tools to customers worldwide. Selection includes tool room and CNC lathes, horizontal and vertical mills, radial and upright drills. As well as Hydraulic shears. Designs and manufactures sheet-glass edge grinding and polishing machines and bevelling machines. Drilling machines for double-sided drilling of sheet glass.

Designs and manufactures sheet-glass edge grinding and polishing machines and bevelling machines. Drilling machines for double-sided drilling of sheet glass. Provides machine tools to customers worldwide. Selection includes tool room and CNC lathes, horizontal and vertical mills, radial and upright drills. As well as Hydraulic shears. Designs and manufactures sheet-glass edge grinding and polishing machines and bevelling machines. Drilling machines for double-sided drilling of sheet glass.

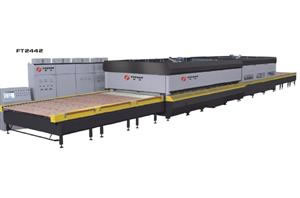

Radiation Flat Tempering Furnace FT

Radiation Flat Tempering Furnace FT

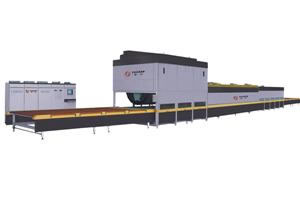

Forced Convection Flat Tempering Furnace CFT

Forced Convection Flat Tempering Furnace CFT

Combined Dual Chamber Flat Tempering Furnace SFT

Combined Dual Chamber Flat Tempering Furnace SFT

Double Row Fan Forced Convection Flat Tempering Furnace NCFT

Double Row Fan Forced Convection Flat Tempering Furnace NCFT

Double-curved Glass Bending Furnace FS-DBT

Double-curved Glass Bending Furnace FS-DBT

Radiation Flat and Bent Tempering Furnace FBTC/FBTL

Radiation Flat and Bent Tempering Furnace FBTC/FBTL

Forced Convection Flat and Bent Tempering Furnace CFBTC

Forced Convection Flat and Bent Tempering Furnace CFBTC

Forced Convection Flat and Bent Tempering Furnace CFBTL

Forced Convection Flat and Bent Tempering Furnace CFBTL

Combined Dual Chamber Flat Tempering Furnace SFT

Combined Dual Chamber Flat Tempering Furnace SFT

Glass Straight-Line Four Edger

Glass Straight-Line Four Edger